I too was once a beginner and I too once owned the cheapest, cruddiest drum kit you could imagine. After years of fiddling with my own gear though and helping dozens of students get the most out of their inexpensive drum sets, I have a few pointers on how to get the most out of every kit.

What follows are 12 Ways to Make Cheap Drums Sound Better:

- New Drum Heads

- Tighten All Internal Hardware

- Inspect and Wax the Bearing Edges

- Check For Drum Head Fit

- Tune Your Drums Properly

- Strategic Muffling

- Invest in Decent Cymbals

- Add a Bass Drum Port

- Experiment With Bass Drum Beaters

- Experiment with Sticks

- Adjust Your Snare Wires

- Hardware Adjustments – Eliminate Those Rattles

So, are you ready to make your kit sound great? Follow along as I guide you through each one of these steps in detail. Here is a list of supplies you will need in order to successfully complete every step:

- Drum Key

- Fresh Drum Heads of Your Choice

- Beeswax

- Bass Drum Port Hole Reinforcement Ring

- Drum Tuner (optional)

- New Bass Drum Beater (optional)

- Philips and Flat Head Screwdrivers

- Pliers – Needle Nose Should suffice

1: New Drum Heads

A lot of times, there is no telling how long a set of drum heads have been on a kit. If you see a ton of scuffs and dents on them though, it’s a fair assumption that it’s been a while since they were changed out.

Quick Tip:

One quick way to see just how damaged and fatigued a drum head is is to remove all tension from the head by loosening all of the tension rods. If the drum head retains it’s smooth, flat surface then it is a relatively fresh head. If the center of the drum head sags severely or massive dents and dings appear, this is an indication that this drum head has seen A LOT of use and is overdue for a change.

Even if there is no apparent damage to a drum head, if it has been on a drum for a long time it is a safe bet that the resonance of that drum head has been negatively affected.

Therefore, when you’re buying a used drum set, usually the first go-to method for improving the sound of a drum set is to replace its drum heads. If you are unsure of what size drum heads to purchase for your new-to-you drums, you’ll want to measure the diameter of the shell itself (not including the hoop installed on the drum) and round to the nearest inch.

A typical 5 piece drum set will have drum dimensions of 14″ for the snare, 12″, 13″ and 16″ for the toms and 22″ for the bass drum, although this can vary greatly depending on the type of drum set you’ve purchased.

Though most drum head manufacturers have drum head packs, you may need to select individual heads if your kit has odd drum sizes. One pack that would work with most “standard” configurations (12″, 13″ & 16″ toms) would be this Evans G2 Clear Standard Pack .

.

Next, we’ll discuss some things you can do while you have the drum heads off to improve the sound of your new kit.

2: Tighten All Internal Hardware

OK, you’ve removed the old drum heads from your shells. This is a PERFECT time to inspect and tighten all of the internal mounting hardware for the lugs and other items bolted to the shell (like tom mounts, air vents, snare throw-offs, etc.).

Most screws which attach hardware to drums have washers on them which, if loose can cause an audible rattle when the drum is played. For this procedure, you’ll most likely just need a philips head screw driver, though on some older drums a flat head or socket head style screw was used.

Go around to each screw and tighten it just so it has a bit of friction. You never want to over-tighten this hardware as this can impact the resonance of your shell.

Quick Tip:

This is an excellent time to check out your lugs as well to make sure that no threads are stripped and that the gaskets located between the lug and the shell are in tact. If any of them need to be replaced, getting those replacement parts can be challenging however there are plenty of drum parts suppliers out there which can help you.

Air vents/grommets are typically easily tightened using a pair of pliers. The same rules regarding over-tightening apply. Don’t do it!

3: Inspect and Wax the Bearing Edges

INSPECTION: Bearing edges are mysterious creatures that have needlessly baffled and intimidated many drummers. While issues with bearing edges are tough to fix – inspecting them couldn’t be easier, especially if you’ve already removed the drum heads.

- Run your finger along the edge and feel for any divots, dents or bumps. You’re looking for your finger to travel smoothly all the way around the diameter of the shell. If you do encounter a flaw, go in for a closer inspection.

- Get down even with the bearing edge so that you can view the entire plane at once (i.e. you can see if the edges are even with each other).

- If you want to get really fancy, go find yourself a smooth, flat and level surface and place the drum down on it. Using a flashlight in the shell, inspect the edges from the outside. There will likely be a little bit of light escaping from the bottom – but the key is that you are looking for the light to be EVEN all around the drum. Any brighter spots could point to bearing edge damage.

- One acceptable exception to this inspection would be the bottom side of a snare drum, which has “snare beds” cut into the bearing edges. These are slight indentations in the opposite sides of the edge where the snare wires run and allow them to freely rattle.

- Repair: Very small issues can usually be fixed with a bit of wood filler and sand paper, but this must be done very carefully. It’s usually best to call upon a local drum builder/repair shop to fix issues with edges as they will likely need to cut an entirely new edge into that side of the drum.

WAXING: This sounds like a tricky operation, but it really isn’t. Applying a small amount of wax to a drum’s bearing edge allows for better tuning and vibration characteristics of the drum head.

Whatever you do, please don’t melt any kind of wax for this. You’ll simply want to acquire some bees wax (though a candle or paraffin would work in a pinch) and apply a small amount to the bearing edge, being careful not to cause any damage to it in the process.

(though a candle or paraffin would work in a pinch) and apply a small amount to the bearing edge, being careful not to cause any damage to it in the process.

4: Check For Drum Head Fit

Next, you will want to double check that the “collar” of your new drum heads (the firmer, rounded edge of the drum head film) fit nicely over the bearing edge of the drum. The most obvious reason for this is to check and make sure you’ve bought the right size drum head, however there are a few more potentially problematic reasons for a bad fit:

If your shells are “out-of-round” or not perfectly circular, it is quite likely that your drum head either flat out won’t fit or it won’t “seat” properly over the edge. Unfortunately, there isn’t much that can be done to salvage severely out-of-round shells. Simply place the new head over the drum and visually inspect that all edges marry nicely with each other around the diameter of the instrument.

Vintage Drums (for the sake of this article, let’s classify this as drums built prior to the 80’s) tend to have thicker shells and slightly larger circumferences. If your new head doesn’t fit properly, a bit of experimenting is in store for you as not all drum head brands are created equal and some may fit better than others. Quick Tip: Instead of buying a whole bunch of drum heads online, go to your local drum/music shop and have one of the sales folks work with you in trying the fit of different brands.

Drum Covering can significantly add to the circumference of a shell, especially in older drums. If this is the case, you may need to trim back some of the drum covering to get the head’s hoop to fit over the drum properly.

Once you’ve completed all of these steps, it’s time to re-install the hoops and hand thread the tension rods through the hoop into the lugs.

5: Tune Your Drums Properly

It is safe to say that tuning drums properly is an art from unto its own, which is why I have dedicated an entire section of this website to the topic of drum sounds and drum tuning . I have and will be adding tons of useful content and guides to that section for how to properly tune drums AND ALSO how to achieve specific drum sounds.

. I have and will be adding tons of useful content and guides to that section for how to properly tune drums AND ALSO how to achieve specific drum sounds.

For the sake of this article however, I’ll give you a condensed version of tuning best practices which you can follow:

- Start by finger tightening all tension rods around the drum on both top and bottom heads.

- Anytime you tighten these rods (either by hand or with a tool), you’ll want to use a ‘star’ pattern to ensure you are distributing the tension evenly around the drum.

- Once all tension rods have been hand tightened, start by tuning the bottom head:

- In the star pattern, give each tension rod a 1/4 to 1/2 turn

- Repeat until the wrinkles in the head have just disappeared

- At this point, you should hear some sort of audible pitch from tapping the head

- Go around the head and tap (with your drum key) it in close proximity to each tension rod.

- Your goal is for each rod location to have the same pitch, so adjust after each tap until all tension rod locations sound the same.

- Repeat the above process for the top head

- Note: the bottom head is usually tuned to a higher pitch than the top head

- If you want to get really fancy – you can attempt to match the resonant note of your drum shell (the note you hear when you tap your shell without heads on it) to the note you’re tuning the drum to. This is a pretty advanced technique though.

Again, a bit light on the details but I’ve offered a lot more in-depth content in the sound and tuning section of this site. Suffice it to say that proper tuning is an art form and takes practice. There are also MANY opinions on proper tuning technique, pitches, etc.

section of this site. Suffice it to say that proper tuning is an art form and takes practice. There are also MANY opinions on proper tuning technique, pitches, etc.

6: Strategic Muffling

Muffling is definitely a personal preference and in my opinion, is often overdone but remains a solid tool in your belt for getting drums to sound the way you want them to.

Bass Drum: Most folks reach for pillows and blankets to stuff inside their bass drum, which works perfectly well. Make sure to play around with how much the muffler contacts the batter and resonant heads, as a slight change can have a HUGE impact on the sound of the kick drum. I personally like to use a thin pillow which barely touches the batter side head but touches the resonant head a bit more.

Snare Drum: In most cases, I recommend letting the snare drum sing! On occasion, I have been known to take my wallet out of my back pocket and stick it on the edge of the drum to cut down on some of the ring and overtones. This is especially the case in low volume scenarios or with a metal shell snare drum. Getting a set of O-Rings is a great way to control the overtones (and to keep your wallet from getting stolen at the gig). They just plop neatly on top of the drum head and usually do the trick.

is a great way to control the overtones (and to keep your wallet from getting stolen at the gig). They just plop neatly on top of the drum head and usually do the trick.

Toms: This is usually where drummers tend to fiddle around the most as there are so many different sounds you can go for with your toms. A well tuned tom with the right heads might not need any muffling at all as a nice sustaining drum (especially floor toms) can be quite pleasing. Using O-Rings, moon gel or even a patch of Kleenex with gaffer tape can help cut down the sustain and overtones. A lot of drummers forget about the bottom/resonant heads though, which is where a lot of the sustain comes from.

7: Invest in Decent Cymbals

“You get what you pay for” is a phrase which holds especially true when it comes to cymbals. Most cheap, beginner drum set actually come with a set of cymbals, however these instruments might as well be used for trash can lids as they are not durable (you will warp them – guaranteed), and they also sound about as good as trash can lids do.

Nothing makes a decent sounding drum set sound worse than horrible sounding cymbals.

The reason I chose the word ‘invest’ for this heading is because cymbals aren’t generally cheap. But anything is usually better than what is included in beginner drum sets. Most major cymbal manufacturers (Zildjian, Sabian, etc.) seel ‘starter sets’ which typically consist of a set of hi hats, a crash cymbal and a ride cymbal. A good example of this is the Zildjian Planet Z Starter Set which you can pick up for about $250. These are definitely not the creme de la creme of cymbals, however they are durable and sound decent for the money.

which you can pick up for about $250. These are definitely not the creme de la creme of cymbals, however they are durable and sound decent for the money.

As with most things in this article, there is no replacement for heading to your local drum shop, grabbing a stick and trying out various cymbal makes and models. You will quickly learn what type of sound you gravitate towards.

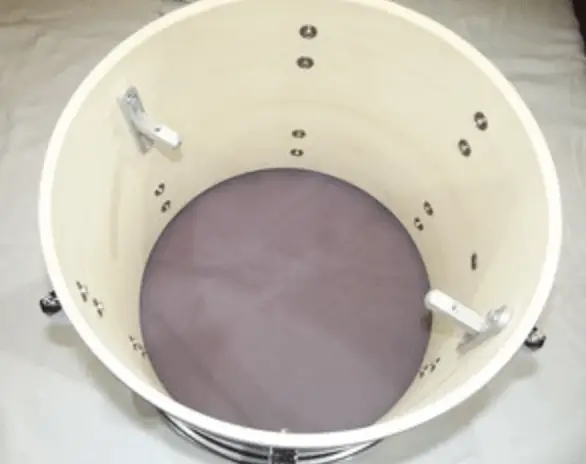

8: Add a Bass Drum Port

If a bass drum is not sufficiently vented, it will likely be very resonant and sound a bit like a basketball. This is fine if you’re a jazz drummer, a genre where this sort of sound is generally desired. Furthermore, the response from your bass drum pedal will also be very ‘live’ and creates a much different playing feel.

But if you’re more of a rock, country, hip-hop, etc drummer – you’ll likely want some sort of venting in your front head.

It is very common place for most drummers to add a hole (or port) to the front, resonant bass drum head. This accomplishes several things:

- Sufficient Venting – Air is allowed to freely escape the drum, allowing the drum heads to resonate freely without air pressure interfering

- Muffling – Because of the ventilation, the drum will naturally not be quite as resonant and produce a punchier sound.

- Microphone Placement – It is common for sound engineers to stick a microphone inside of the bass drum. Having a port in the front head allows for this to be done easily, without necessitating the removal of the front head.

You can either cut a DIY port yourself, though without reinforcement or a cutting template, you’ll be much more likely to ruin a perfectly good bass drum. I would recommend getting a purpose made drum head port hole template such as this one to take the guess work out of it.

such as this one to take the guess work out of it.

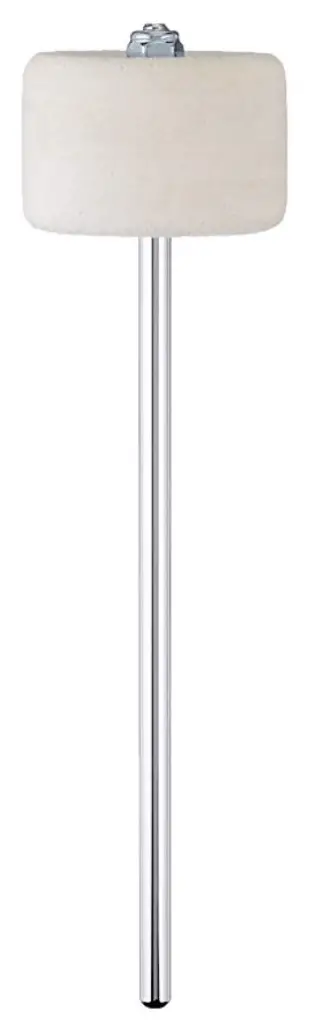

9: Experiment with Bass Drum Beaters

There are various weights and materials to play with when it comes to bass drum beaters. All beater shafts are universal, meaning that you can easily swap different manufacturer’s beaters into your existing bass drum pedal. The most common materials used for bass drum beaters are (in order from softest to hardest):

Felt: The classic beater is made of felt and provides a soft, smooth attack which focuses the sound of the bass drum more on resonance.

Wood: These beaters are not very common but provide a bit more attack while still retaining the warmth of felt.

Plastic: This material is incredibly durable and is popular with a lot of heavy hitters as it also provides clear attack.

Acrylic: This is essentially the opposite end of the spectrum as acrylic is a pretty hard material and results in a very bright and sharp attack.

Double Sided: There are several beaters out there which are double sided, allowing you to switch to a different material depending on what type of gig you’re going to be playing.

Quick Tip:

You’ll often see drummers affix a kevlar sticker to the batter bass drum head, right where the beater makes contact with it. This not only provides some reinforcement for the drum head itself and prolonging its life, but it also has some impact on the sound resulting in more attack when the drum is played.

As you can see, there are a lot of options here and like with everything else, experimentation is key…and also quite fun!

10: Experiment with Sticks

While the sticks themselves make some difference in sound, the stick tips are probably going to have a bigger impact on the sound of the drums…and even more so…the cymbals. The two main options here are wood tips or nylon tips.

Wood tips are just an extension of the stick itself and are formed as part of the lathing process for the stick. They produce a very natural, perhaps somewhat muted sound when used.

Nylon tips are oval shaped nylon sleeves which are slid over and glued to the end of the stick. Nylon tips produce a much brighter sound, primarily because the material itself is a little bit harder.

One downside to using sticks with nylon tips is that they have a tendency to leave marks on cymbals and drum heads. Additionally, if the nylon tip comes off during play, the wood underneath is likely more dowel shaped and can actually inflict some damage to your heads.

11: Adjust or Replace Your Snare Wires

If your snare drum is old and the drum heads are worn out, it is a safe assumption that the snare wires (or simply called snares) likely haven’t been replaced in a long time, maybe never. While these tend to be more durable than a drum head, some attention here could make a decent sounding snare into a great sounding snare!

A great indication for the condition of your snares is to simply turn your throw-off off and look at the wires in a slackened state. If the individual strands are obviously damaged, bent or crossing each other – it’s high time for a new set.

As with anything, there are a wide range of snares available on the market with a wide variety of price points to match. Just like with drum head fit, I would recommend trekking to your local drum shop which is likely to have a decent selection of snares available. They will definitely be able to advise you on the best set of snares for the sound you are going for.

Alternately, if you’re not too picky but recognize the need for a new set and just want a recommendation, Gibraltar makes some good basic snare wires. A slight step up might be a set of wires from PureSound

makes some good basic snare wires. A slight step up might be a set of wires from PureSound .

.

12: Hardware Adjustments – Eliminate Those Rattles!

Cymbal stands, snare stands, drum thrones, hi hat stands and bass drum pedals all of a lot of adjustments and moving parts. To eliminate excess noise on your kit, make sure that all adjustments have been made and tighten any wing nut or screw you see.

Some hardware also have separate memory locks on them so that it can ‘remember’ how the hardware was configured after you’ve taken it apart and collapsed the stand. These tend to be likely suspects for excess rattling.

Additionally, the hardware affixed to each drum (lugs, brackets, tension rods, etc.) can all be a source of rattles. I wrote an in-depth article about making a snare drum sound better . Some of the advice in that article addresses how to reduce drum hardware buzzing specifically.

. Some of the advice in that article addresses how to reduce drum hardware buzzing specifically.

Related Questions

How do I make cymbals sound better?

Sadly, cheaply made cymbals will never sound as good as their expensive counterparts. If spending money on good cymbals isn’t an option, ensure that the cymbals you do have are mounted correctly with plenty of felt, and adjust your playing technique to make sure you are getting the most resonance out of the instrument as possible. I wrote a detailed article about how to make cymbals sound better if you want to get more detailed information.

if you want to get more detailed information.

How can I make my drums quieter?

There are many methods to decreasing the volume of drums including various muffling solutions (both free and products you can purchase), as well as soundproofing the environment you are in so that sound doesn’t escape the room you’re in as much. I have a whole section of this website devoted to drumming quietly , so dig into those articles to get more details.

, so dig into those articles to get more details.